On Track: Steel Crazy

Summer construction season is upon us! Projects from basement remodels to state-of-the-art commercial high rise buildings, to tiny houses, to residential renovations, to new home builds - all can certainly reap the rewards of steel stud framing. While they aren’t for every project and some folks would argue steel studs are more expensive than their wood counterparts - let’s start with a deep dive into why professional contractors & seasoned DIYers prefer metal studs for almost every application.

Steel studs are nice and straight (every time!), making them an incredibly common sense construction material. Steel studs come in numerous gauges to cover a wide variety of applications. They do not split. They are flame retardant. They do not rot. They do not warp. They do not mold. They are insect proof. They install quicker than wood. They are always the same size. Steel studs can be time-savers too because loading materials into the job site will go faster. An average person can carry a bundle of ten steel studs fairly easily. Not too many people can carry ten wood studs around!

Installing steel studs is done in a similar manner to installing wood studs. There is a floor and a ceiling plate – with steel studs, these are called a track. Steel studs are placed on 16-inch centers, the same as wood studs. Where it is most common to build a wood stud wall on the ground and then raise it into position - with steel studs, it is most common to build the wall in place. It’s easy to join steel studs together to make them longer. This is often a problem for wood studs in a building where the ceilings are high, and the elevator isn’t tall enough to take in the length of stud you need. Just construct the size your need with steel! Additionally, the sheetrock on a wall framed with steel studs and track is going to be a flatter surface than the sheetrock on a wood-framed wall. Because steel doesn’t swell or shrink, there will be no need to worry down the road about sheetrock expansion. Best of all, cutting metal studs is quiet and fast work with a tin snip (no power tools needed), and there is no sawdust to clean up once finished!

Beyond the obvious advantages of steel framing for commercial construction, steel studs are also a great choice for finishing off a basement or a bathroom build or remodel. One of the main concerns in basement/bathroom renovation is the effect of moisture over time. Wood does not react very well in humid conditions and tends to warp, contract, or expand. This leads to a less-stable structure, and nails can even pop out as the wood changes shape and size. Steel studs, on the other hand, have no such worries. Metal does not warp when exposed to moisture, ensuring that your studs stay strong.

Besides the ease of creating basic partition walls - steel studs - being light in weight, are an excellent choice for creating the framework for valances, ceiling, and wall motifs. Steel framing is also the perfect choice for tiny house builds as the lighter weight of the structure allows for greater ease in towability.

When you factor in that steel studs are easier to use, take less time to set up, are consistent and precise, plus incredibly economic -- from tiny homes to high rise residences -- any argument of higher purchase costs are cancelled out. As with all projects, safety is key. When working with steel studs, be sure to wear gloves (the metal can be very sharp) and goggles for eye protection.

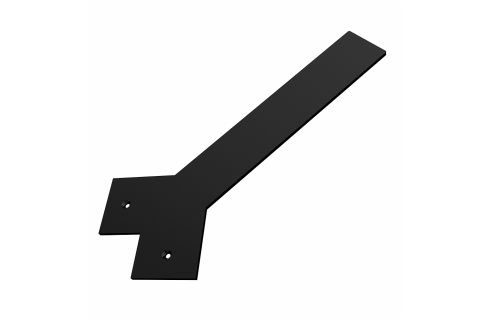

Federal Brace is proud to offer new solutions for mounting surfaces and riggings on metal stud construction. Our Made in the USA Metal Stud Cantilever Plate utilizing Stud Brace Technology is in stock & ready to ship! Check out www.FederalBrace.com or call toll-free (877) 353-8899, 8:30 AM - 5 PM EST for additional ideas and design assistance.